ALUMINUM FOUNDRY

- Gravity die casting for piece weights of 0.5kg to 60kgs.

- Production capacity of 1200MT per annum.

- 2 Electrical melting furnaces with capacity of 500kgs each.

- 3 Electrical holding furnaces with capacity 0f 250kgs each.

- Nitrogen rotary degassing unit.

- Density Index Analyzer.

- Thyristor power controlled drop bottom heat treatment furnace with weight capacity up to 1000kgs.

- Cold Box Shooter with capacity up to 25 liters.

IRON FOUNDRY

Horizontal Moulding Line

- DISA MATCH (24×28) high pressure technology with Scada PLC controlled sand plant.

- Production capacity of 9600 MT Per annum.

- Applicable mould size 710X610X255 mm.

- High speed configuration of 120 moulds per hour due to unique DISA Blow/Squeeze mechanism.

- Green sand casting for piece weights of 0.8kg to 65kgs.

- Inductotherm 1100 KW IGBT furnace for induction melting at the rate of 2 MT per hour.

- Fully customized in house Cold Box Core Shooter with capacity 0.3 liters to 25 liters and Shell Core Shooter with capacity 0.3 liters to 15 liters.

- Fully equipped digital sand testing laboratory.

- In house fettling facility, shot blasting facility and paint shop.

IRON FOUNDRY

Vertical Moulding Line

- DISA Vertical High Pressure Moulding Line Technology.

- Applicable mould size.

- Hight 535mm

- Width 650mm

- Thickness 120-340mm

- High speed configuration of 150 molds/hrs.

- Scada PLC control system

- Green sand casting for piece weights of 0.5kg to 25kg.

INVESTMENT CASTING

- Casting technology: Lost Wax Foam process.

- Material grades: Aluminium alloy, Stainless Steel, Carbon Steel, Low Alloy Steel or any other material as per request.

- Material standards: ASTM, ALSI, DIN, EN and JIS standards.

- Size: 450×450×400mm (L*W*H), Diameter – 500 mm.

- Weight:0.1kg to 40 kgs.

- Minimum wall thickness: 3mm.

- Value added service: Surface treatment, hand polishing and assembly.

FORGING

- Forging technology: Close Die Forging.

- 2.5-ton Hydraulic hammer and 250-ton power press.

- Material grades: Case Hardening Steel, Low Carbon Steel, Medium Carbon Steel, Alloy Steel, Stainless Steel, Mild Steel, Duplex Stainless Steel and EN-series.

- Single Piece weight range 0.2 kg to 55 kgs.

- Size: 500 MM Length, Diameter – 150 MM.

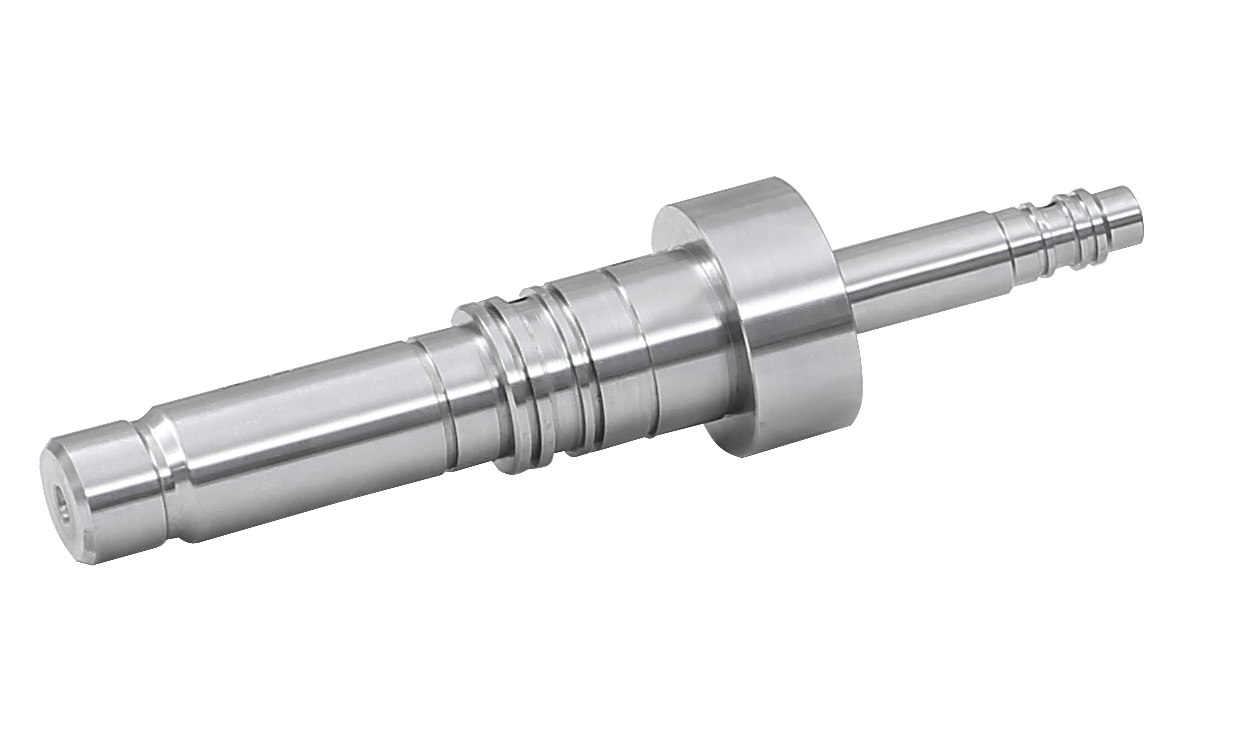

MACHINE SHOP

- World class CNC machine shop – Turning centers, VMCs and HMCs with pallet changer.

- Machining capabilities to manufacture Aluminium, Cast Iron, Ductile Iron, Stainless Steel and Forged Parts.

- Currently machining more than 1 million parts per annum.

- Mazak Flexible manufacturing line with 32 Pallet system suitable for 630x630x900 mm dimensions and weight up to 500 kgs.

- Accuracy level maintained at 0.01 mm in linear and 0.025 mm in geometrical dimensions.

- Capability for roughness value Rz 4 minimum maintained.

- In house tool room facility.